Manufacturing

CrateDB empowers the manufacturing industry by enabling real-time analytics on large volumes of data from IoT devices, sensors, and production systems. With its scalable, high-performance database, manufacturers can monitor equipment health, optimize processes, and improve predictive maintenance. CrateDB's ability to handle structured and unstructured data ensures seamless integration of various data types, driving efficiency and innovation in smart factories.

Key Benefits of CrateDB for Smart Manufacturing

Real-Time Analytics: With CrateDB, you can analyze massive streams of data from connected devices in real-time and enhance decision-making for smarter, more efficient production processes.

Scalability: CrateDB seamlessly scales to handle millions of data points per second. It supports the growing data needs of smart factories as they evolve and expand.

Flexibility: CrateDB supports structured, semi-structured, and unstructured data. It easily integrates diverse data sources such as machine logs, sensor outputs, and IoT device data.

Optimized Smart Manufacturing Operations

Predictive Maintenance: Continuously monitor equipment health to predict potential failures. Minimize downtime and maximize asset uptime through proactive interventions.

Process Optimization: Use real-time data to identify production inefficiencies and bottlenecks. Adjust operations in real-time for optimal throughput and resource allocation.

Quality Control in Smart Manufacturing: Integrate AI and machine learning models to detect defects and maintain high-quality standards. Reduce waste and enhance product quality through real-time insights.

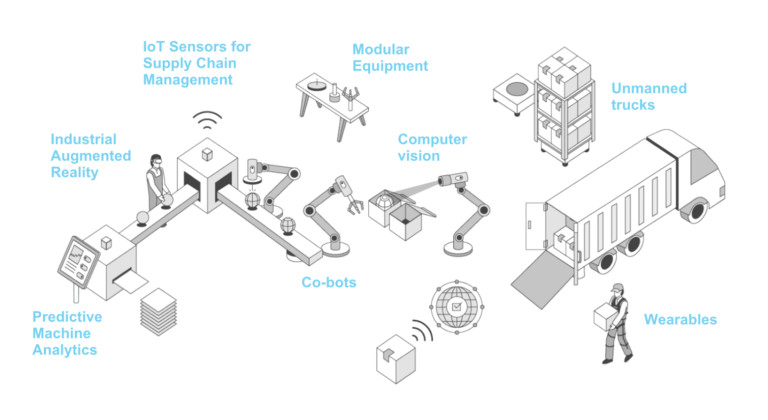

Built for Smart Manufacturing and Industry 4.0

Advanced Search & AI Integration: Leverage CrateDB’s powerful search capabilities to quickly filter large datasets. Integrate AI-driven analytics for predictive maintenance, demand forecasting, and smart automation.

Cost-Effective Scalability: CrateDB offers a cost-efficient solution, with a distributed architecture built to scale alongside smart factories. Achieve high performance and reliability without excessive infrastructure costs.

Enabling the Future of Smart Manufacturing: CrateDB supports the digital transformation toward smart manufacturing, enabling real-time data collection and analysis for smarter, more agile production environments. Stay competitive by leveraging cutting-edge data technologies in automated, data-driven factories.

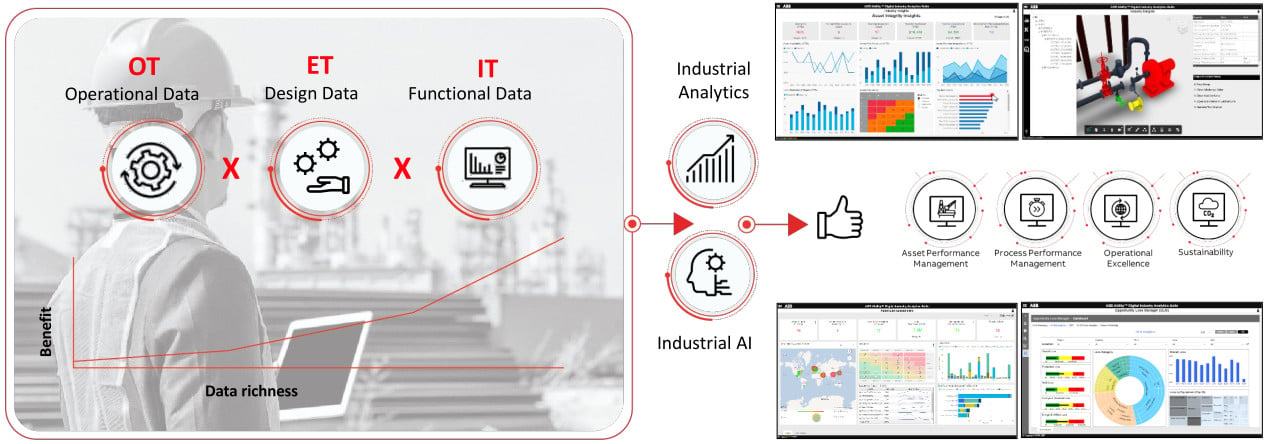

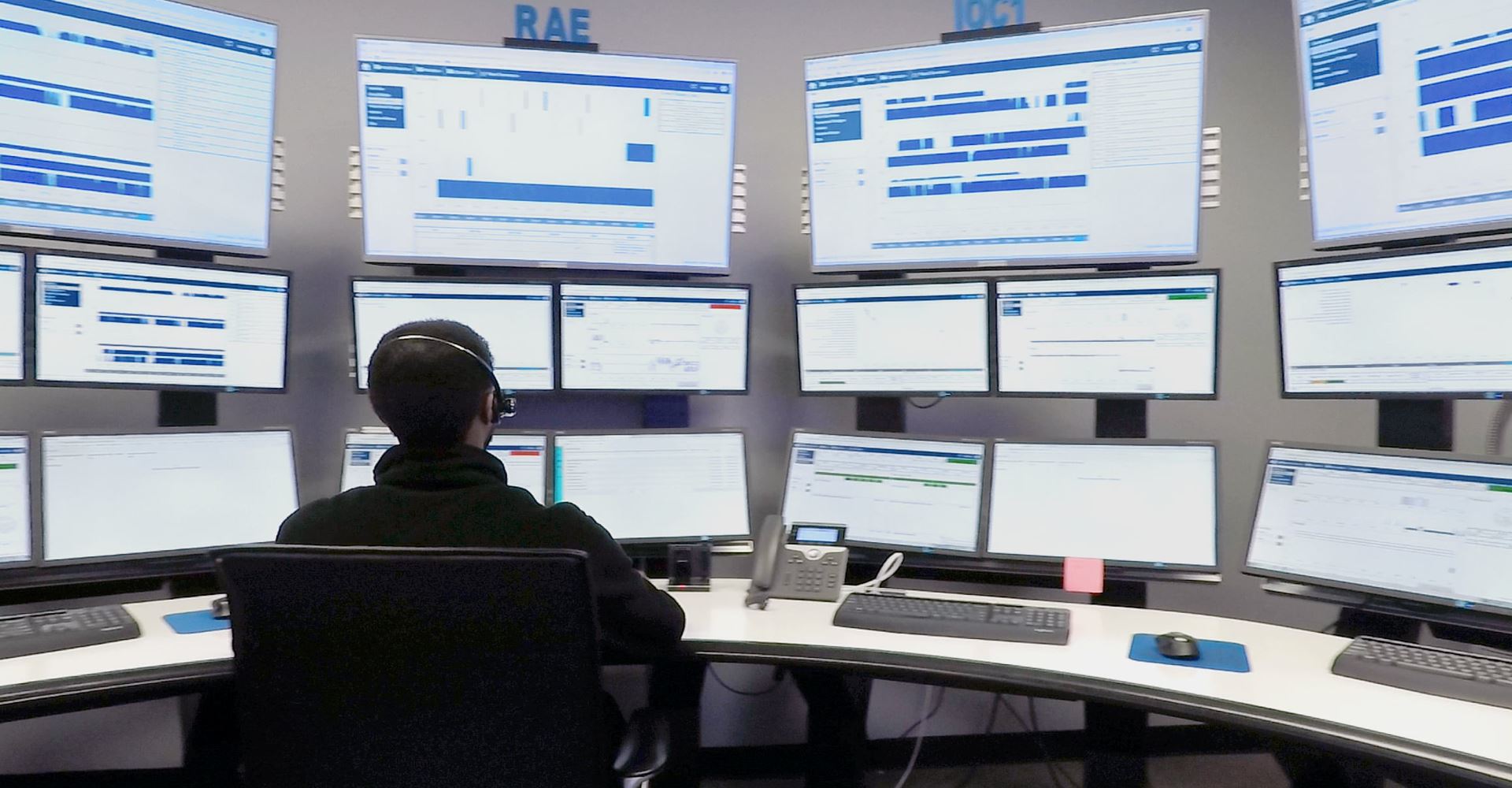

Case study #1: ABB

Less than 20% of data generated by industrial companies is used and ABB's flagship digital solution wants to change that. ABB Ability Genix, launched in 2020, caters to multiple sectors, combining data-centric approaches with AI/ML and domain knowledge to deliver contextually rich data. It expands beyond sensors and devices to include engineering, design, and IT data, integrating them into the platform with pre-made adapters and ABB's domain knowledge.

Key objectives

- Perform very fast time-series queries, both with hot and cold data.

- Process different workloads with no impact on performance.

- Detect real-time issues through window function aggregation.

| 1 Mill values/sec | 30k to 120k event/sec |

| Data ingestion | Event retrieval |

Case study #2: ALPLA

ALPLA is a world leader in the area of packaging solutions, producing high-quality packaging for Coca-Cola, Unilever, and other brands in the food, drinks, cosmetics and cleaning industries. ALPLA employs 20,900 employees at 181 locations across 46 countries.

Key objectives

- Provide real-time dashboards to 1.000s of employees.

Main technical challenges

- Get quick insights into production data mix (ERP data/Sensor Data, Quality Data).

- Store large amounts and a variety of data (relational, JSON & timeseries data) for real-time access across 180 plants.

- Plan for simple growth when adding new lines and plants, fully integrate with existing systems.

Curious to learn more?

Related Blog Posts

Transforming Industrial Processes: AI for Production and Logistics

2024-06-21Artificial Intelligence (AI) plays a significant role in manufacturing and supply chain logistics, being a crucial part of the industries' digital transformation process. As part of the Smart ...

Navigating Digital Transformation: Role of Data in Smart Manufacturing

2024-06-03The rise of smart manufacturing is revolutionizing the industrial landscape. This transformation, influenced by growing amounts of complex data, extends beyond big plants and large-scale ...

Overcoming Challenges in Smart Manufacturing with Digitalization

2024-05-24In today's age of rapid digital transformation, the manufacturing industry is increasingly leveraging IoT technologies to improve efficiency and productivity. However, this shift has challenges, ...